The Industry’s Choice for Turbine Engine/Rotating Machine Measurement & Balancing, Non-Contact Measurement, Semiconductor/Solar Metrology Systems and Signal Generator Diagnostic Equipment

MTI Instruments, a Vitrek brand, is a US-based manufacturer of precision tools, systems and solutions for clients requiring the precise measurement and control of products and processes and for the development and implementation of in-situ precision measurement for the automation of manufacturing, assembly and complex machinery operation. Our product solutions are used in engine vibration analysis systems for military and commercial aircraft applications, industrial manufacturing/production markets and research, design and process development markets. MTI maintains a Quality Management System (QMS) in accordance with ISO9001:2015.

Latest News!

Rotating Engine & Vibration Balancing Systems

Are you looking for balancing systems? Commercial aviation companies and the U.S. military rely on MTI Instruments’ vibration analysis and engine trim balance solutions to quickly identify any jet engine problems, saving the time and cost of engine repair and maintenance.

PBS eXpress

PBS-4100+ Gen4 Portable Vibration and Balancing System

PBS-4100+ Portable Vibration and Balancing System

This portable vibration analysis and engine trim balance system for commercial and military aviation is designed to swiftly pinpoint engine problems and eliminate avoidable engine removals. Rapid configuration and intuitive user interface make this system straightforward and uncomplicated to use.

TSC-4800A Tachometer Signal Conditioner

The TSC-4800A is a programmable tachometer conditioner for engine monitoring and testing systems.

The state of the art speed resolver/signal conditioning unit capable of working with all types of engine speed signals. Whether you are testing engines with a long tooth or short tooth embedded N1 signal, if you have engines with older high-voltage tachometer generators, or if you are testing engines with the new offset tooth design, the TSC-4800A will condition all of these types of signals.

Accumeasure Capacitance Sensors

Technology-driven measurement solutions for high resolution gap applications.

The Accumeasure product line features capacitive sensor products for high-resolution gap and displacement measurements that require a high level of stable and repeatable accuracy. A capacitive sensing system consists of a probe and amplifier. Capacitive measurements can be performed in a multitude of environments using non-contact passive capacitance probes that are not affected by magnetic fields, temperature, humidity, nuclear radiation, and pressure. This is largely due to the nature of the rugged and passive capacitance probes.

Extremely high-precision and high linearity amplifiers make these systems ideal for critical measurements in X-Y stages, rotating spindles, shaft position, armature gap, disk position, and piezoelectric positioning applications. MTI engineering guarantees a highly stable, accurate, and low-noise amplifier design with an attention to fast response time.

Thousands of MTI’s products are used globally in the semiconductor, automotive, aviation, electronics, and medical industries. As the leader in capacitance technology with decades of experience, MTI stands behind the quality and performance of the most demanding user environments.

Accumeasure HD

Picometer Resolution with up to 2 mm range. Accuracy to 0.01% of full-scale range. It has built-in digitally controlled low pass cutoff filters, adjustable sample rate and data logging features. Display your data right on your PC or HMI. USB and Ethernet ports provide digital connectivity at 100 megabit speeds. The amplifier has Digital Output only as analog output would only corrupt the high-resolution data. 1-2 channels in a small compact enclosure. Only 24 VDC industrial power is needed.

Accumeasure D

Sub-micron resolution with up to 12 mm range. Accuracy to 0.01 % of the full-scale range. It has built-in digitally controlled low pass cutoff filters, adjustable sample rate, and data logging features. Display data right on your PC or HMI. USB and Ethernet ports provide digital connectivity at 100 megabit speeds. Analog outputs are also available. 1-4 channels in a small compact enclosure. Only 24 VDC industrial power is needed.

Accumeasure 9000 and 500 Rack

AS-9000 is an analog output, high-resolution, capacitance-based instrument that provides the perfect solution to many previously unattainable measurement applications. The AS-500 is a multi-channel rack system that accepts six capacitance amplifiers (AS-562-PA or AS-563-PA). They deliver nanometer-level resolution for ultra-high-precision measurements (and work with most MTI probes). The AS-9000 and AS-500 rack require the probes to have BNC connectors or SMA to BNC adapters. Both have built-in power supplies and an oscillator to drive the amplifier boards.

Accumeasure MicroCap PCB OEM Boards for Embedded Applications

Our smallest OEM PCB footprint. Sub-micron resolution, with up to 25 mm range. 0 to + 10-volt analog output.

Requires +/- 15 VDC analog power supply. Linearity accuracy to 0.1 % of full-scale range up to 5kHz bandwidth. The frequency response must be specified at the time of order.

A system consists of a printed circuit board (PCB) capacitance amplifier, probe, and coax cable. The customer provides the enclosure and power supply. MTI provides the connector interface. Probes require an MCX connector or BNC, depending on the amplifier chosen.

Accumeasure AS-56X PCB OEM Boards for Embedded Applications

Sub-micron resolution, with up to 25 mm range. 0 to + 10-volt analog output. Requires +/- 15 VDC analog power supply. Linearity accuracy to 0.05 % of full-scale range, up to 5kHz bandwidth. The frequency response must be specified at the time of order. The frequency response is set by plug-in low pass filter. Offset and gain pots for user adjustments. The Accumeasure AS-562 can also operate with ungrounded targets, typically for semiconductor wafer applications.

A system consists of a printed circuit board (PCB) capacitance amplifier, probe, and coax cable. The customer provides the enclosure and power supply. MTI provides the connector interface. Probes require an MCX connector or BNC, depending on the amplifier chosen.

Accumeasure Probes

MTI provides a wide range of various probe types for all the above amplifiers. They include robust stainless-steel probes with integral leads or quick disconnect coaxial connectors. We also have ultra-thin polyimide probes, PCB probes, and push-pull probes for ungrounded targets. MTI designs and manufactures probes for OEM or single sensor sales. If you don’t see what you need, contact us for a quote on a custom probe.

Probes need to be mated with a capacitance amplifier. Some probes have integral leads, and others require selecting a coaxial cable assembly. MTI works with OEM clients to make custom probes meeting specific application needs.

1D/2D/3D Laser Systems & Fiber Optic Sensors

MTI Instruments offers high speed, high resolution and highly accurate 1D laser sensors (non-contact linear position sensor) for measuring displacement and position. Our laser measurement systems allow easy position setup and alignment with its visible laser position spot (check out laser safety standards before handling laser sensors). Quality and process control applications that require accurate warpage, alignment, lead position on integrated circuits, sheet and web thickness measurements can be precise and repeatable as our 1D laser displacement measurement sensors are equipped with an auto gain feature making it unaffected by surface (i.e. energy reflections) texture, color or stray light. Our large line up of non-contact displacement sensors including laser triangulation sensors provide operating distances to 300mm, measurement ranges to 200mm and measurement resolution to less than 1 micron.

This high speed 2-dimensional laser profile sensors are ideal for quality control and production applications for dimensional measurements, thickness, profiling, metal bending, weld bead, weld seam following and used as laser gap measurement. When it comes to laser measurements such as metal or plastic welding, 3D material inspection, component alignment, tire depth, angle measurements and more, MTI laser scanner heads can be easily integrated with PLC through HMI in quality control environment.

Microtrak 4: 1D Laser Displacement Sensor

The Microtrak™ 4 is the ultimate laser displacement sensor for measuring height, thickness, displacement, vibration, and more, with a sensor frame rate of 40k Samples/sec. and linearity of 0.03% FSO (Full Scale Output) accuracy and repeatability are assured.

Microtrak 3: 1D Laser Displacement Sensor

High resolution, high speed laser displacement sensor (non-contact linear displacement sensor) utilizes the latest CMOS sensor technology that challenges even the most difficult measurement applications. The Microtrak™ 3 is an essential measurement tool for process automation, quality control and tool automation control, for applications such as, thickness measurement, dimensional displacement, part profiling, vibrations testing, build-up measurement, and much more.

Microtrak 3 Laser Thickness Gauge System

The Microtrak 3 Laser Thickness Gauge System combines our proven laser triangulation sensors with a modular controller that operates either as a standalone solution or with a PLC/PC. It simplifies laser thickness measurement applications through high-speed internal sampling and digital thickness computation, reducing errors often encountered with traditional analog summing methods.

ProTrak HD: 2D/3D Laser

The ProTrak HD long range profiling laser displacement sensor is built to satisfy the most demanding automated dimension, angle, curvature and height in the industrial application. At a fast speed of 6,000 frames per second and up to 2.5µm resolution, it also has measuring of up to 800 mm.

Fiber Optic MTI 2100 Fotonic Sensor

The MTI-2100 features advanced fiber-optic non-contact sensor using reflectance electronic technologies for precise measurements of displacement, active vibration control, position, and distance for dynamic measurement in cryogenic, vacuum | high pressure, or in a high magnetic field or harsh environment.

Fotonic Plug-In Module

Sensitive fiber optic measurement sensors for nanomotion and vibration measure dynamic edge position, displacement, and vibration at frequencies up to 500 kHz. The unique fiber optic probe design can accommodate a wide range of target reflectivity or shape, making it ideal for wide variety of applications such as ultrasonic horn vibration or Piezoelectric materials studies.

Portable Signal Simulators/Calibrators with Laboratory Equipment Accuracy

Our Signal Simulator Product Line Offers Affordable Laboratory Precision in a Field Ready Package.

Having a Precision Portable Signal Simulator and Calibrator is a must-have for engineers and technicians working in a variety of fields – from routine troubleshooting and maintenance to calibrating and tuning advanced equipment such as eddy current probes, strain gauge amplifiers, or charge amplifiers for jet turbine vibration analysis.

1520 Precision Portable Signal Simulator and Calibrator

The 1520 Precision Signal Simulator is a NIST-traceable signal source for testing and calibrating sensor-driven systems. This portable and easy-to-use system lets technicians bring laboratory-grade precision into the field or onto the factory floor or flightline. Applications include accelerometers, flow meters, pressure transducers, tachometer generators, and microphones. An intelligent sensor database lets operators simulate a wide variety of sensor types and build custom simulations using SQL queries.

MTI’s 1520 Precision Signal Simulator is Made in the USA and combines a rugged and ergonomic design with a battery that supports all-day use. This field-upgradable unit supports software updates along with additional sensors and features. Importantly, this WiFi-enabled device can be remotely controlled via a smartphone so that a single technician can perform troubleshooting and diagnostics. Technicians like its intuitive user interface and appreciate that its touchscreen is easy-to-use with a gloved hand.

1510A Portable Signal Generator and Calibrator

A portable signal source for calibration, testing, troubleshooting, and system monitoring.

The 1510A Precision Portable Signal Generator and Calibrator is a must-have for engineers and technicians working in a variety of fields – from routine troubleshooting and maintenance, to calibrating and tuning advanced equipment such as eddy current probes, strain gauge amplifiers, or charge amplifiers for jet turbine vibration analysis.

Semiconductor/Solar Metrology Systems

One of the most important components of your electrical devices is the semiconductor wafers that help regulate the electricity coursing throughout the system. A key consideration when dealing with these components boils down to the wafer thickness measurements. Ensuring these meet industry standards becomes easier when you utilize MTI Instruments’ array of wafer measurement tools.

We specialize in helping our customers get the most accurate proportions to ensure power flows freely and safely throughout the system. Our wafer measurement tools have helped engineers from across a wide range of industries and disciplines keep their electrical devices in good working order and help identify where improvements can be made.

Other Products from Vitrek’s Family of Brands

Embrace the Future of Precision Measurement with MTI Instruments

Navigating the complexities of turbine engine measurement, balancing, non-contact measurement, and semiconductor/solar metrology systems requires a partner you can trust. MTI Instruments, with its industry-leading solutions, is that partner.

Our advanced tools and systems are catalysts for change in your operations. They’re designed to help you maintain the highest standards of precision, efficiency, and quality in an ever-evolving industrial landscape.

From state-of-the-art balancing systems for turbine engines and innovative non-contact systems to comprehensive metrology systems for semiconductors and solar panels and reliable signal generator diagnostic equipment, MTI Instruments has what you need. Explore our product portfolio in more detail.

Non-Contact Measurement Devices Support a Variety of Industries

In the rapidly evolving technological landscape, non-contact devices have emerged as game changers across various industries. These innovative tools, particularly non-contact measurement devices and displacement sensors, are revolutionizing processes, enhancing efficiency, and driving productivity.

These devices use technologies such as lasers, infrared, ultrasonic waves, or capacitive and eddy current principles to capture data, ensuring accuracy, speed, and safety in numerous applications.

Why Major Aircraft & Turbine Engine Manufacturers Trust MTI Instruments

In the highly demanding and precision-driven world of aircraft engine and turbine manufacturing, trust is a hard-earned commodity. When it comes to reliable, accurate, and innovative measurement solutions, MTI Instruments stands out as one of the more trusted partners — and for good reason.

MTI Instruments is a leading global provider of precision measurement solutions and non-destructive testing equipment. With over five decades of industry experience, MTI Instruments has been at the forefront of delivering innovative products that meet the exacting needs of major aircraft engine and turbine manufacturers worldwide.

One of the defining factors that set MTI Instruments apart is its commitment to innovation. With a consistent desire to invest in research and development, MTI Instruments ensures its products stay ahead of the curve, offering the most advanced solutions in the market. This commitment to innovation is exemplified in products like the PBS-4100+ Gen4, which redefines the standards for jet engine vibration analysis and balancing.

Beyond its innovative product line, MTI Instruments offers fantastic service for all clients. Our highly skilled professionals work closely with customers to understand and deliver on their unique needs with our various customized solutions. This customer-centric approach has earned MTI Instruments a reputation for reliability and trustworthiness among major aircraft engine and turbine manufacturers.

As a part of the Vitrek family, MTI Instruments benefits from the backing of a brand known for its high-quality electrical safety test and measurement equipment. Vitrek’s commitment to quality, accuracy, and reliability echoes in every product and service that MTI Instruments provides.

About Vitrek’s Portfolio of Brands

Since 1990, Vitrek has provided innovative global solutions for high voltage test and measurement including electrical safety compliance testers, multi-point high voltage switching systems and graphical power analyzers. Vitrek is the parent company of several industry related brands, including XiTRON, MTI Instruments, GaGe, Signatec and KineticSystems. Our portfolio of products include test and measurement solutions including high-voltage, safety and compliance testing solutions, non-contact measurement devices, portable signal simulators and calibrators, semiconductor/solar metrology systems and turbine engine/rotating machine balancing. Our data-acquisition brands add a wide array of board-level data acquisition and integrated real-time signal recording system solutions from GaGe, Signatec, and KineticSystems. Vitrek also supplies precision high voltage measurement standards to national laboratories and calibration labs around the world. This unique and complementary combination of product and engineering capabilities positions Vitrek as a leading provider of test solutions serving the photovoltaic, medical equipment, power conversion, electrical/electronic component, semiconductor, aerospace and appliance industries. Vitrek is an accredited ISO 17025 Calibration Laboratory and ISO 9001:2015 Certified organization.

MTI Instruments, a Vitrek brand, is a US-based manufacturer of precision tools, systems and solutions for clients requiring the precise measurement and control of products and processes and for the development and implementation of in-situ precision measurement for the automation of manufacturing, assembly and complex machinery operation. Our product solutions are used in engine vibration analysis systems for military and commercial aircraft applications, industrial manufacturing/production markets and research, design and process development markets. MTI maintains a Quality Management System (QMS) in accordance with ISO9001:2015.

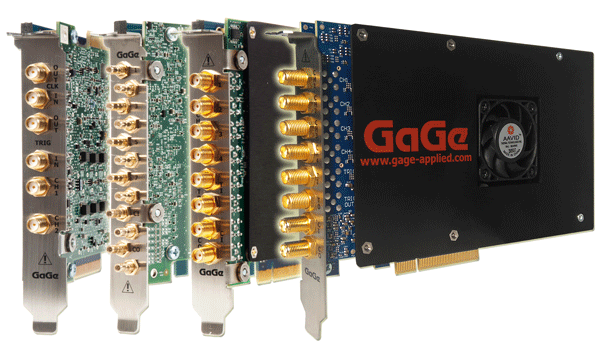

GaGe, a Vitrek brand, established in 1987, is a US-based producer in high-speed data acquisition solutions featuring a portfolio of the highest performance Digitizers that are renowned for sustaining the maximum effective number of bits (ENOB) over a wide signal frequency range with quality signal conditioning and signal fidelity features, PC oscilloscope software, and powerful SDKs for custom application development used in applications for signal analysis, lidar, ultrasound imaging and non-destructive testing, communications, particle physics, mass spectroscopy and more. GaGe brand products include solutions previously available from Signatec and KineticSystems

GaGe’s product offering includes PC-based high-speed and real-time signal acquisition, processing and recording systems. GaGe systems combine the performance features of oscilloscopes and spectrum analyzers delivering fully integrated solutions. GaGe’s advanced systems are used in signal technology applications for aerospace and defense, SIGINT, radar, high-speed communications, laboratory test & measurement, medical imaging and more.