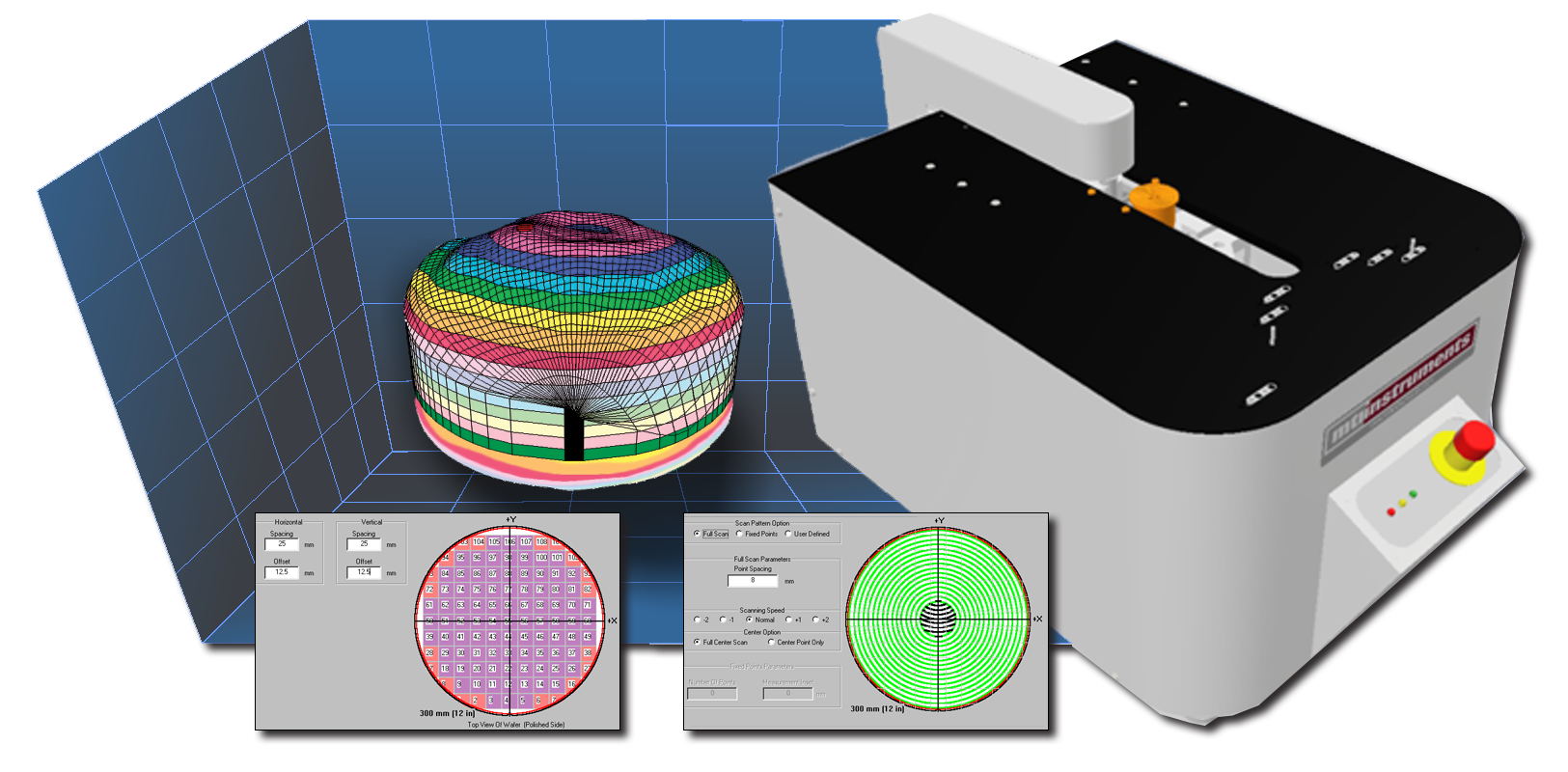

MTI Video: Wafer Inspection and Metrology Tutorial (Proforma 300i)

https://www.youtube.com/watch?v=nGkbpG2sz_k Learn More Download this brochure to learn more about the Proforma 300i wafer measurement system for semiconducting and semi-insulating wafers. This article in AZO Sensors also provides information.